In many workshops and manufacturing settings, residual magnetism can develop in metal tools and machine parts, causing them to cling to one another or attract stray debris. This build-up of magnetic force not only hampers precision but also extends cleaning time and accelerates wear on cutting edges. One practical remedy is the use of demagnetizing coils, which create a controlled alternating magnetic field that gradually reduces the net magnetisation until the component returns to a near-neutral state.

How Demag Coils Operate

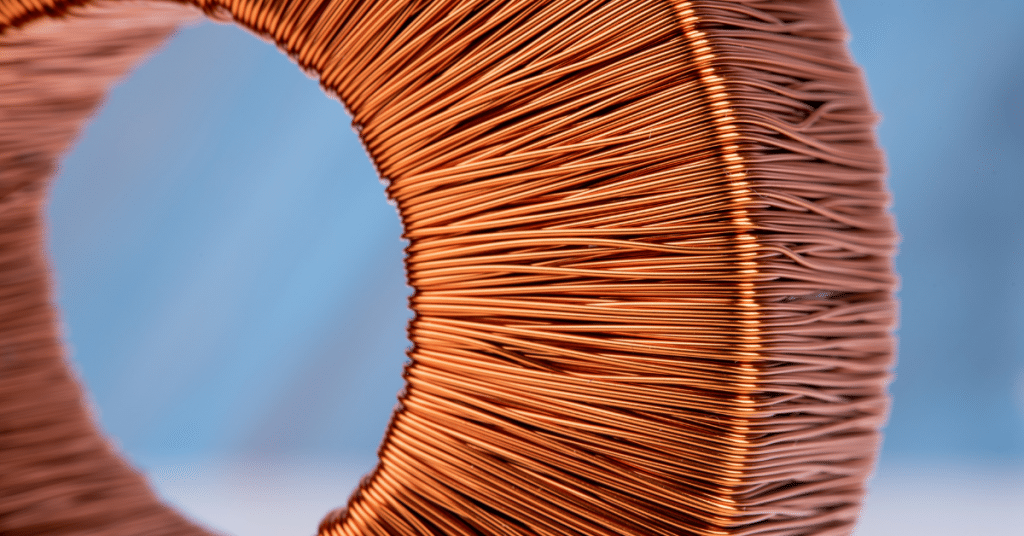

A demag coils system typically consists of a copper winding connected to an AC power source. When activated, the coil produces an alternating field whose strength is slowly decreased, either by physically withdrawing the part from the coil’s centre or by lowering the current in the winding. As the magnetic field oscillates and diminishes, the internal magnetic domains in the metal reorient in random directions rather than remaining aligned. By the time the field reaches zero, the part’s residual magnetism has been largely neutralised, restoring its original non-magnetic condition without the need for complex controls or extensive operator training.

Common Applications

Precision machining operations often leave tools slightly magnetised, which can lead to metal chips clinging to end mills or drill bits and compromising the quality of cuts. Similarly, in electronics assembly, unwanted magnetism in jigs, fixtures or test fixtures can interfere with sensitive sensors or circuit boards. In non-destructive testing, background magnetism may produce false indications during magnetic particle inspection, making it difficult to detect real flaws. By using coil demagnetisation before machining, assembly or inspection, technicians eliminate unwanted magnetic effects, improving part quality and reducing rework.

Selecting the Right Unit

Choosing an appropriate coil demagnetiser involves matching the machine’s capabilities to your parts and workflow. Larger workpieces require a coil bore with sufficient clearance, while heavier items benefit from a higher-power unit that treats parts more quickly. Some models offer adjustable controls or built-in timers to automate the power-reduction cycle, which can be helpful in high-volume environments. Portable bench-top units suit smaller workshops, whereas fixed or handheld versions can be placed right at the point of use, saving operators from carrying heavy parts back and forth.

A Practical Example

In one small toolroom a technician noticed that end mills were consistently picking up steel filings after each cut, despite routine cleaning. Introducing a bench-top coil demagnetiser at the workbench cut the average cleaning time by more than half and eliminated scratches caused by chips embedded in the tool flutes. Over a fortnight, tool life increased noticeably, helping the shop maintain tighter tolerances and reducing the frequency of costly tool replacements.

Safety and Maintenance

Regular inspections and basic upkeep keep a coil demagnetiser reliable and safe. Operators should make sure that power cables remain free of cracks and that the winding insulation shows no signs of wear. Units must stay dry to prevent corrosion and electrical faults, and proper grounding protects against shocks. By following simple manufacturer guidelines and performing a quick visual check before each use, teams can avoid downtime and extend the service life of both the machine and the parts it treats.

Integrating into Daily Routines

Incorporating coil demagnetisation into standard work processes is straightforward. Place the unit near machining centres or inspection tables so that parts can be treated as part of normal handling. Train operators on the correct sequence—power up the coil, treat the part, then reduce the field—and document the step in operating procedures. Tracking metrics such as defect rates, tool-wear patterns and cleaning time before and after installation helps demonstrate the benefits and justifies wider adoption.

Final Thoughts

Coil demagnetisation offers a simple yet effective way to eliminate unwanted magnetism across a range of metalworking and inspection tasks. With minimal training and low maintenance, these systems improve part quality, reduce rework and extend tool life. By selecting the right unit and building treatment into daily routines, workshops and assembly lines can keep magnetic interference from affecting productivity and precision.