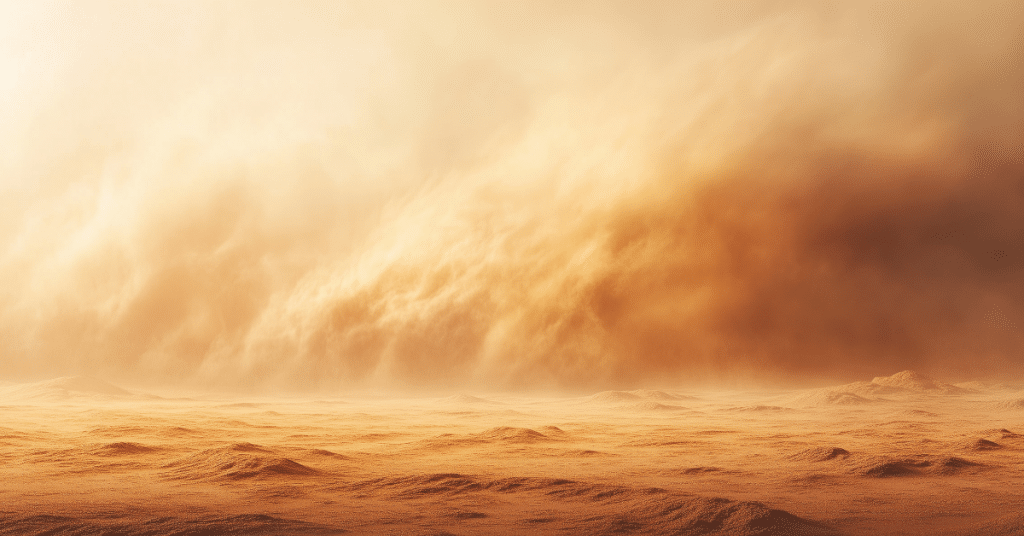

Managing dust is a constant challenge across construction sites, mines, and industrial areas. It affects visibility, worker safety, and air quality. Using the right dust suppression methods helps reduce airborne particles and keeps operations running smoothly. With modern technology, companies now use reliable equipment and systems that handle dust before it spreads into the environment.

Why Dust Control Matters

Uncontrolled dust can cause several issues. It can reduce visibility on-site, increase health risks for workers, and even damage machinery over time. Investing in a proper dust control system prevents these problems. Controlling airborne dust isn’t just about keeping areas clean—it’s also about creating safer and more efficient working conditions.

When dust levels are reduced, workers can operate more effectively. It also helps sites comply with environmental and safety standards. Whether on haul roads, processing plants, or open-pit mines, keeping dust under control is essential for long-term sustainability.

How a Dust Suppression System Works

A dust suppression system is designed to manage and reduce dust at its source. These systems can use water, chemicals, or a combination of both to bind particles and prevent them from becoming airborne.

In large-scale operations, systems often use high-pressure sprayers or nozzles to apply a fine mist of water. This mist settles dust particles without soaking the work area. Modern systems are automated, adjusting spray pressure and timing based on the level of activity or wind speed.

For roadways or loading areas, continuous sprays or fogging setups work well. They create a barrier between the dust source and the air, improving air quality across the site.

Types of Dust Suppression Solutions

Different environments need different dust suppression solutions. Here are some common types used across industries:

- Water-based systems: These are simple and effective for most operations. They rely on fine mist sprays that capture airborne dust.

- Chemical additives: In some cases, water alone isn’t enough. Special binding agents can be added to make dust particles heavier, preventing them from rising.

- Fogging systems: Fogging systems use specialized nozzles to create microscopic water droplets that absorb and control dust particles efficiently.

- Mechanical control methods: These involve using barriers, windbreaks, or covers to contain dust in specific areas.

Each method has its advantages. The key is to choose a system that suits the size of the operation and the type of material being handled.

The Role of Water Spray Systems

A water spray system for dust control is one of the most effective ways to handle dust. These systems use a combination of pumps, pipes, and nozzles to distribute fine sprays of water across dusty areas.

They’re often placed in crushing plants, conveyor transfer points, and stockpiles. The water helps capture airborne dust, allowing it to settle quickly. This not only improves visibility but also protects workers from respiratory hazards.

Water spray systems can be manual or automated, depending on site needs. Automated systems are often connected to sensors that activate sprays when dust levels rise beyond safe limits.

Using Fog and Mist Cannons for Dust Suppression

Modern technology has introduced advanced equipment like Fog Cannons and Misting Cannons for better dust management. These machines release high-pressure mist that covers large open areas.

The mist captures dust particles in the air and causes them to fall to the ground, reducing the spread of fine materials. Mist cannons are especially useful in mines, construction zones, and material handling areas where traditional methods can’t reach.

Fog and mist cannons are mobile, meaning they can be moved easily across different sections of a site. They are powerful, energy-efficient, and ideal for use in both wet and dry conditions.

Long-Term Benefits of Proper Dust Suppression

Choosing the right dust suppression system improves working conditions and protects both people and equipment. When dust is under control, machines operate better, filters last longer, and maintenance costs go down.

It also improves community relations. Nearby residents and businesses are less affected by air pollution or debris from industrial operations. In many industries, effective dust management has become part of standard operating practices.

Environmental compliance is another major benefit. Proper dust control supports sustainable site management, helping companies meet health and safety requirements.

Real-World Application Examples

- Mining: Open-pit mines use dust suppression systems to control emissions from haul roads and blasting areas.

- Construction: Building and demolition sites rely on fog cannons to keep air clean during heavy-duty work.

- Material handling: Conveyor belts, crushers, and screening stations use misting cannons to keep airborne particles low.

- Road maintenance: Water-based sprays are used to control dust on unpaved surfaces.

Each of these examples shows how different industries use technology to maintain safer environments and reduce environmental impact.

Final Thoughts

Controlling dust is about more than compliance—it’s about improving safety, protecting equipment, and reducing pollution. With effective dust suppression, operations become cleaner and more efficient. Using tools like fog cannons, misting cannons, and water spray systems for dust control offers practical, long-term solutions for dust-prone areas.

Industries that invest in proper dust suppression solutions see better results, smoother operations, and safer working environments for everyone involved.