Modern construction, mining, and demolition projects often rely on specialised equipment to process and prepare materials. Instead of buying machinery outright, many companies prefer crusher and screener hire services. This approach allows access to professional-grade equipment without the high cost of ownership or maintenance.

The Purpose of Crushing and Screening

Crushing and screening are important stages in material processing. Large rocks, concrete, and waste materials are crushed into smaller pieces, making them easier to handle, transport, and reuse. Screening separates materials by size, ensuring that each output meets specific requirements for later use.

Many industries, including mining, construction, and recycling, rely on crushing and screening plant hire to manage these operations efficiently. By hiring the right equipment, contractors can complete work faster and maintain consistent quality.

Benefits of Crushing Plant Hire

Choosing crushing plant hire offers flexibility for both short-term and long-term projects. Renting equipment gives companies the advantage of using advanced technology without the financial pressure of purchasing and maintaining machinery.

Another benefit is access to expert operators. Many hire services include trained professionals who know how to handle the machines safely and get the most out of them. This not only boosts productivity but also reduces the risk of downtime caused by misuse or technical errors.

Mobile Crushing Plant Hire for On-Site Work

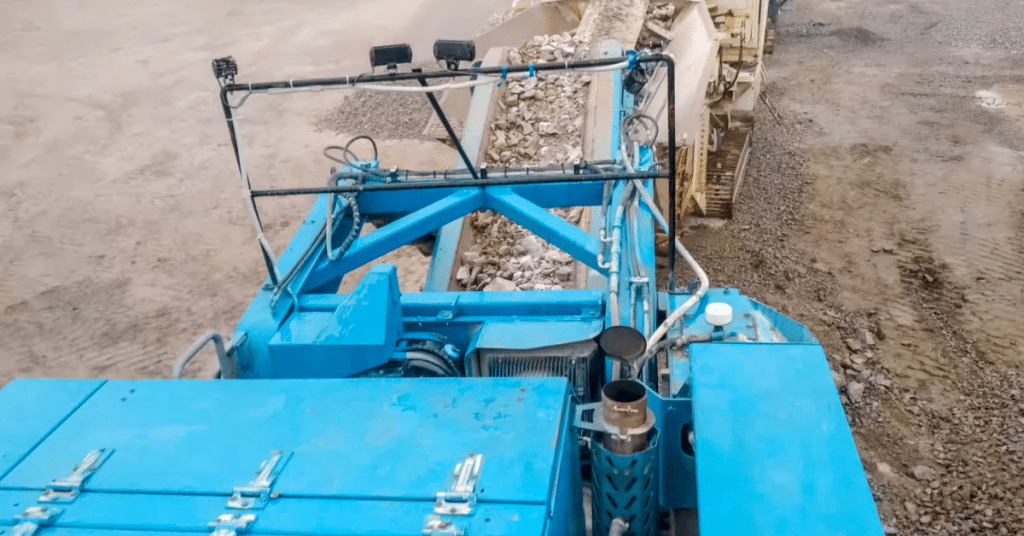

For projects that require flexibility and mobility, mobile crushing plant hire is a popular choice. These mobile units can be transported directly to the worksite, allowing materials to be processed on location instead of being moved to another facility.

This saves time and reduces transport costs. Mobile plants are ideal for construction sites, roadwork projects, and demolition jobs where different types of materials need to be crushed or screened quickly. They also help reduce environmental impact by cutting down on unnecessary material movement.

How Screening Equipment Improves Efficiency

Screening machines are essential in separating materials by size, shape, and quality. With mobile screening plant hire or screening plant hire, contractors can easily classify materials such as sand, gravel, and crushed stone.

Using the correct screening equipment helps ensure that only suitable materials are used for each stage of the project. This improves efficiency and reduces waste. Well-screened materials are easier to mix, transport, and recycle for new construction.

Mobile Screener Hire for Remote Projects

In many construction and mining projects, access to remote areas can be challenging. Mobile screener hire is useful in such conditions because the equipment can be easily moved between locations.

These machines are designed for rough terrain and can handle high-capacity workloads. Mobile screeners provide quick and accurate sorting, which makes them suitable for projects that require precise material separation on the go.

Screening Plant Rental for Short-Term Needs

Not all projects need equipment on a permanent basis. For short-term or seasonal work, screening plant rental offers a cost-effective option. Rental agreements give access to advanced machines without the need for large investments.

This is particularly helpful for smaller contractors or companies managing multiple projects at once. It provides flexibility to use the right equipment only when needed and return it when the work is complete.

Environmental Benefits of Crushing and Screening

Crushing and screening are not just about productivity—they also support sustainability. By using hire equipment to process demolition debris or leftover materials, companies can reduce waste sent to landfills. Recycled materials such as crushed concrete or gravel can be reused for new roads, pavements, or foundations.

Using mobile crushing plant hire equipment reduces transportation needs, cutting fuel use and carbon emissions. This makes it a practical and eco-friendly choice for construction and demolition projects of all sizes.

Real Example of Crushing and Screening in Action

During a recent road upgrade project, a construction team used crusher and screener hire services to process old asphalt and concrete. The mobile machines allowed the team to crush the materials on-site and reuse them for the new road foundation.

This saved time, reduced transport costs, and lowered the project’s environmental footprint. It also demonstrated how reliable hire equipment can make large-scale work more efficient and sustainable.

Choosing the Right Equipment for the Job

When selecting crushing and screening equipment, the type of material and scale of work should guide the choice. For large, ongoing projects, a complete crushing and screening plant hire setup may be best. For smaller or changing jobs, mobile units offer better flexibility.

Consulting with equipment providers can help identify the right machines for each phase of a project. Most hire services offer support in setup, operation, and maintenance, making it easier for contractors to focus on completing their work.

Final Thoughts

Whether it’s crushing plant hire, mobile screener hire, or screening plant rental, these services play a key role in construction and mining operations. They provide access to reliable, high-performance machinery without the long-term commitment of ownership.

By choosing flexible and affordable equipment hire options, contractors can keep their projects running smoothly, cut costs, and contribute to a cleaner, more sustainable work environment.