Magnetic separators are integral components in various industries, used to remove ferrous and non-ferrous materials from a product stream. These separators help ensure the quality and safety of products, prevent machinery damage, and enhance operational efficiency. Whether in mining, recycling, or food processing, magnetic separators play a key role in numerous applications. In this article, we will explore the different types of magnetic separators and their uses.

Types of Magnetic Separators

Magnetic separators come in several types, each designed to meet specific industry needs. Below are some of the most common types and their uses.

Magnetic Drum Separator

The magnetic drum separator is a well-known magnetic separator used for the continuous extraction of ferrous contaminants from materials. The drum is mounted at the end of a conveyor belt, and as material passes through it, the magnetic field attracts metal particles, removing them from the stream. This type of separator is highly effective in processing large quantities of material and is often used in recycling operations and industries dealing with bulk material handling.

Magnetic Conveyor Systems

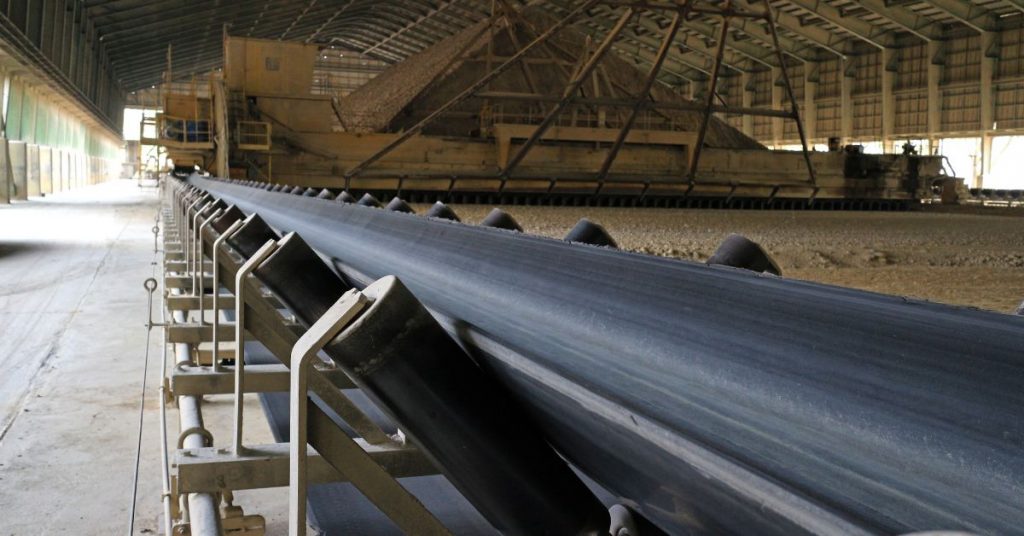

A magnetic conveyor system is a highly effective tool for moving materials in industrial settings while simultaneously removing ferrous contaminants. These systems are designed to integrate magnetic separation directly into the conveyor belt, making them an ideal choice for continuous operations. For instance, in the food processing industry, magnetic conveyor systems help ensure that food products are free from metal debris, ensuring safety and quality.

Magnetic Separator Conveyor Belts

Magnetic separator conveyor belts are used to move materials along a conveyor while simultaneously separating ferrous metals. These belts work by utilizing the magnetic field of a rotating drum or pulley to capture metal particles as the material passes over the belt. This type of magnetic separator is especially useful in large-scale operations, where efficient and continuous material handling is needed.

Cross Belt Magnetic Separator

The cross belt magnetic separator is used to separate ferrous materials from non-ferrous ones in a variety of industries, including mining, recycling, and plastics. This separator is mounted across the conveyor belt and uses a magnetic field to attract and remove metal contaminants. It is often used in bulk material handling applications where metal contamination must be removed before further processing or manufacturing.

Wet Drum Magnetic Separator

For materials in liquid form or slurry, the wet drum magnetic separator is the ideal choice. This separator uses water to help separate ferrous contaminants from liquids or slurry materials. Wet drum magnetic separators are often used in the mining industry for the processing of ores, such as iron ore beneficiation, and are also utilized in industrial wastewater treatment processes.

High Intensity Magnetic Separator

The high intensity magnetic separator is designed for removing very fine ferrous contaminants from materials. It generates a stronger magnetic field than standard separators, allowing it to capture even the smallest metal particles. This separator is widely used in the food and pharmaceutical industries to ensure that products are free from metal contaminants that could be harmful to consumers.

Magnetic Head Pulley

A magnetic head pulley is an essential tool for removing ferrous contaminants from conveyor systems. The pulley is placed at the head of a conveyor belt, and as materials pass over it, the magnetic field pulls metal contaminants off the material stream. Magnetic head pulleys are highly efficient and often used in large-scale operations where continuous material flow is necessary.

Magnetic Roller Separator

The magnetic roller separator is designed to remove small ferrous contaminants from granular materials like grains, seeds, and chemicals. The rotating drum of the separator is covered with magnetic material, which attracts ferrous particles as they pass through the system. These separators are commonly used in the food processing industry, where product purity is of the utmost importance.

Importance of Magnetic Separators in Industry

Magnetic separators play a crucial role in several industries, improving efficiency, safety, and product quality. In the mining industry, magnetic separators are essential for iron ore beneficiation and coal beneficiation, helping to remove impurities from raw materials and enhance the quality of the final product. Similarly, in recycling operations, magnetic separators are used to separate metal contaminants from recyclable materials, ensuring that valuable metals are recovered and non-ferrous materials are free from metal debris.

In the food processing industry, magnetic separators are used to remove harmful metal contaminants from food products, ensuring consumer safety. The use of material handling magnets helps improve the efficiency of product transport, reducing the risk of contamination during handling.

Tramp Metal Removal

Another significant use of magnetic separators is in the removal of tramp metal, which refers to unwanted metal pieces that can cause damage to equipment or compromise the quality of the final product. Suspended conveyor magnets and suspended magnetic separators are ideal for removing tramp metal from material flows, preventing costly repairs and ensuring that the processing equipment remains in optimal condition.

Similarly, tramp metal magnets are commonly used in mining and recycling operations to capture metal debris that could damage machinery. These separators improve the longevity and performance of the equipment, reducing the need for maintenance and extending the life of the system.

Conclusion

Magnetic separators are indispensable tools in industries ranging from mining and recycling to food processing and material handling. Whether you need a dry magnetic separator for fine particle separation or a ferrochrome magnet for heavy-duty applications, there is a magnetic separator to meet every need. By effectively removing metal contaminants, these separators not only enhance product quality but also protect equipment and improve operational efficiency.

With various types like the magnetic drum separator, magnetic separator conveyor belts, and high intensity magnetic separator, industries can ensure the smooth flow of materials and maintain high standards of safety and quality. By incorporating magnetic separators into industrial processes, businesses can reduce downtime, lower maintenance costs, and ensure the best possible outcomes for their operations.